As most people know it’s just a matter of time until technology breaks down, wears out, and needs to be replaced. The same goes for medical equipment. Whether you have a small office or a large practice, at some point, you’ll need to think about ophthalmic equipment service and repair. When it comes to the tools you need to do your job and provide the best possible care for your patients, it’s important to have a maintenance and care plan in place. This will reduce the number of last-minute service and repair calls, and will ensure that your equipment will last for years.

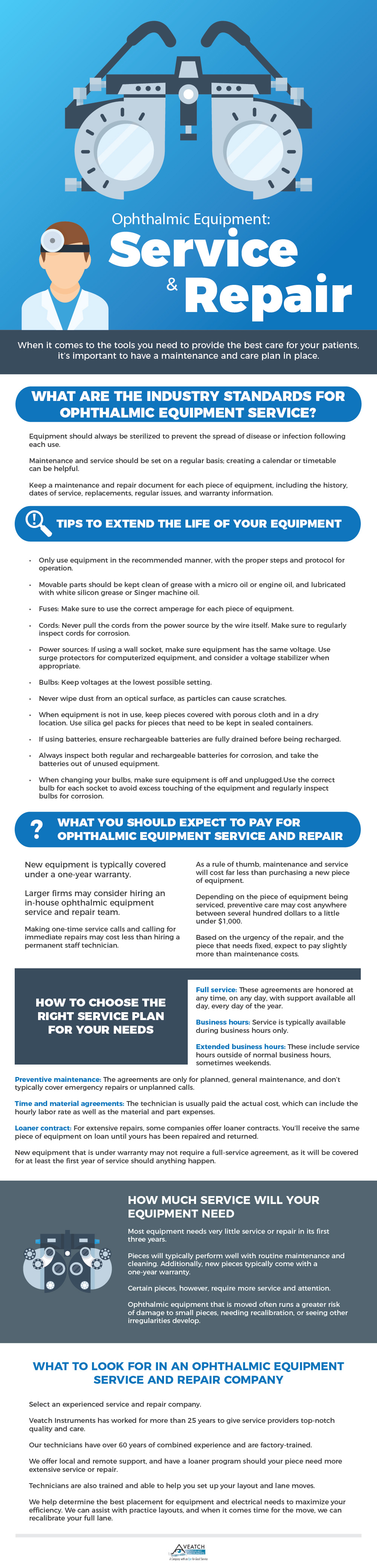

What are the Industry Standards for Ophthalmic Equipment Service?

Equipment should always be sterilized to prevent the spread of disease or infection following each use.

Maintenance and service should be set on a regular basis; creating a calendar or timetable can be a helpful tool.

Some pieces, like dusting, checking light bulbs, lubrication and cleaning of small parts, should be done on a weekly or monthly basis; while more involved tasks should be done on an annual basis per manufacturer recommendations and warranty details.

For example, some pieces may need an annual service call for general maintenance, which can include re-calibration. However, if the piece is moved, it might be a good idea to have the calibration checked following the move.

Keep a maintenance and repair document for each piece of equipment, including the history, dates of service, replacements, regular issues, and warranty information.

How to Extend the Life of Your Equipment

There are a few things you can do to make sure your ophthalmic equipment is able to handle your increasing number of patients and high usage.

- Love Your Equipment and it will love you back. The pieces that make up your equipment are highly sensitive, and can have very delicate components. Make sure that each time you use the equipment, you are only using it in the recommended manner, with the proper steps and protocol for operation. Put tools back in their allotted spaces, rather than leaving them lying on desks or in pockets.

- Caring for Optical Surfaces: These surfaces can include the mirrors, prisms, lenses, beam splitters, windows and glass plates on many pieces of ophthalmic equipment, which have often had extensive preparations. The surfaces are highly polished to prevent any warping or irregularities, and some pieces are then coated to ensure that the surface is optimally prepared for use.

- Cleaning and General Maintenance of Common Equipment Components

- Movable parts should be kept clean of grease with a micro oil or engine oil, and lubricated with white silicon grease or Singer machine oil. It’s important to follow manufacturer’s suggestions and recommendations for the care of each piece and component.

- Fuses: These are used to keep electrical currents from being overloaded, so it’s important to make sure that you use the correct amperage for each piece of equipment. This means not swapping out fast-blow and slow-blow fuses, and never bypassing the fuses. You should always keep extra fuses with the correct amperage near each piece of equipment.

- Cords: Never pull the cords from the power source by the wire itself, as that can damage the cords. Make sure to regularly inspect cords for corrosion; if any corrosion is found, scrape or file it from the cord contact points.

- Power sources: There are several different power sources you may find yourself using regularly. If you are using a wall socket, make sure that your equipment has the same voltage, otherwise seek out an appropriate transformer. Use surge protectors for computerized equipment, and consider a voltage stabilizer when appropriate.

- Bulbs: Make sure to keep your voltages at the lowest possible setting. When there is a surge, you risk the burst of power blowing out the bulbs. Try to keep these settings as low as possible, when the pieces are in use. If you have the lamps on, especially in pieces like microscopes, do not move the equipment, as even slight movement can crack or break the bulb filament.

Coatings are typically a very thin chemical film that can help to maximize the transmission and reflection of light, and to prevent loss of light and undesired wavelengths. Different pieces of equipment utilize different chemical coatings, so before handling or caring for each individual optical surface, study the manufacturer’s recommendation.

Never wipe dust from an optical surface, as the particles can cause scratches that can negatively affect the results from the piece of equipment. Take extra precautions near optical surfaces, especially when using a sharp instrument, wearing jewelry, or with long fingernails, as even the slightest touch can affect the piece’s effectiveness. Always hold optical surfaces on the edge, while wearing gloves or with a tissue to keep oils from touching the element.

It’s important, though, for hygienic purposes and to maximize the performance level, to keep elements clean. When cleaning the various components, make sure to follow each step as set out by the manufacturer. Failure to do so can cause damage to the equipment and end up costing more in the long run through repairs or replacements. Also, keep in mind that each cleaning can remove or wear out some of the optical surface coating.

When equipment is not in use, keep each piece covered, and take preventative measures against fungus, which can cause costly damage to lenses. Keep equipment in a dry location, and use a dehumidifier, if necessary. Porous cloth covers are preferred for covering equipment, and use silica gel packs for pieces that need to be kept in sealed containers.

If you’re using batteries, ensure that rechargeable batteries are fully drained before being recharged, and keep in mind that as time passes, the battery’s lifespan will gradually get shorter. Always inspect both regular and rechargeable batteries for corrosion, and take the batteries out of unused equipment; they could leak and cause corrosion to the equipment

When you change your bulbs, make sure that the equipment is off and unplugged, and that the bulbs are cool. Use the correct bulb for each socket to avoid excess touching of the equipment; oil deposits on your fingers can leave permanent marks on the bulb, and can cause shadows.

Bulbs should be regularly inspected to make sure that there is no corrosion. If any corrosion is found, it can be scraped off; if it is only on one side, shift the bulb one half turn. Review the filaments for continuity, to make sure that they aren’t bent, and check the welding points.

How to Purchase Long-Lasting Equipment

Keeping equipment working properly starts from the beginning, before any pieces have even been purchased. As soon as a need is identified, it’s important to do research and look for recommendations for long-lasting equipment.

There will always be some pieces that will need to be replaced; most often, these include the basic components like light bulbs, power sources, and fuses. Taking proper care of these parts will help the overall equipment last longer.

The best bet when purchasing any ophthalmic equipment is to work with a company like Veatch Instruments; companies that understand equipment, repair and service equipment, and might actually manufacture pieces of equipment will have a much deeper understanding of what it takes to produce a piece of ophthalmic equipment that lasts.

A consultation with a company that understands equipment, like Veatch Instruments, can provide guidance and direction for the best equipment for a practice of any size. Analyzing the amount of use each piece will get, as well as the attention and care that will be given to each piece, can set any practice up for success with long-lasting, durable equipment.

What You Should Expect to Pay for Ophthalmic Equipment Service and Repair

New equipment is typically covered under a one-year warranty, so paying for the service and repair of new pieces should be minimal.

Some larger firms may consider hiring an in-house ophthalmic equipment service and repair team that will be available at any time. This can save them time and money when it comes to frequent repairs, tune-ups and preventative maintenance of the various pieces of equipment used on a daily basis. However, hiring a technician can be pricey, especially considering that, for most of the time, there will be no repairs.

Making one-time service calls, and calling for immediate repairs, may cost less than hiring a permanent staff technician, depending on the pieces of equipment that are being serviced. A full lane, for example, will cost more than a slit lamp.

Others have opted to purchase service plans. There are a wide variety of options when it comes to buying a service plan, and the plan can be purchased either for all of the equipment or specific, high-use pieces.

As a rule of thumb, maintenance and service will cost far less than purchasing a new piece of equipment. Depending on which piece of equipment you are having serviced, preventive care may cost anywhere between several hundred dollars to slightly less than $1,000. Based on the urgency of the repair, and the piece that needs fixed, expect to pay slightly more than maintenance costs.

Some pieces, though, like certain optical lenses, may cost more in repair than it would cost to replace. It’s a good idea to keep this in mind and do research to put a maintenance and repair plan in place, so that when something happens, everyone is on the same page and knows what to do.

How to Choose the Right Service Plan for your Needs

Thinking about the care of your equipment can be overwhelming. With so many delicate, critical parts, and so much technical background to keep everything operating properly, most ophthalmic offices choose to work with a professional for the service of the equipment.

The market for service agreements can be vast, with various levels of response times.

- Full service: These agreements are honored at any time, on any day, with support available all day, every day of the year.

- Business hours: Service is typically available during business hours only; eight hours for five days a week is the norm.

- Extended business hours: As it says, these might include service hours outside of normal business hours, and sometimes also include weekends.

- Preventive maintenance: The agreements are only for planned, general maintenance, and don’t typically cover emergency repairs or unplanned calls.

- Time and material agreements: The technician is usually paid the actual cost, which can include the hourly labor rate as well as the material and part expenses.

- Loaner contract: In extensive repairs that may take longer than your business can go without the piece, some companies offer loaner contracts. You’ll receive the same piece of equipment on loan until yours has been repaired and returned.

It’s important to look at the age of your pieces. New equipment that is under warranty may not require a full service agreement, as it will be covered for at least the first year of service should anything happen.

Consider how much the equipment is used. You might think about purchasing a full service contract for primary pieces of equipment that are frequently used, but backup pieces might not warrant the same level of necessary care.

How Much Service Will Your Equipment Need

Most equipment needs very little service or repair in its first three years. Unless there is extensive use outside of the norm, your pieces will typically perform well with routine maintenance and cleaning. Additionally, new pieces typically come with a one-year warranty.

Following that, certain pieces will require more service and attention. For example, slit lamps typically only need routine maintenance, but microscopes, that have a higher level of detail, will more than likely need service and repairs more frequently.

Ophthalmic equipment that is moved around a lot runs a greater risk of having damage to tiny pieces, needing recalibration, or seeing other irregularities develop.

It’s important to remember that well-care-for equipment will hold up much better than equipment that is carelessly maintained. Yes, accidents happen. We’ve seen our share of dropped Binocular Indirect Ophthalmoscopes, and we take care to inspect each part when the equipment is sent to us for repair. Just a quick eyepiece cleaning isn’t sufficient. We will disassemble your BIO to its basic components and clean each piece individually with the appropriate materials. We’ll align the optics, replace the necessary parts, and reassemble it. After it’s been put back together, we use a schematic eye and 20D lens to ensure that the field of view is fused, crisp, and clear.

Digital refractors are a critical part of your practice, and these might be pieces that require a full service agreement. Regular preventative service and general maintenance for this piece is recommended to ensure that your office runs smoothly and provides the best service to your customers. Each unit is disassembled, and the bearings, races, and optical surfaces are cleaned. After the pieces are re-lubricated, the unit is reassembled and realigned. We also disassemble, clean and lubricate the yoke. Attention to detail can make a significant difference in your equipment’s performance.

Some studies have shown that, on average, one-third of the problems reported were caused by the user, one-third are typically easily repaired technical problems, and one-third require more technical knowledge and service.

What to Look for in an Ophthalmic Equipment Service and Repair Company

It’s important to select a service and repair company that has experience in the industry and understands how all the pieces work. Veatch Instruments has been working for more than 25 years to give service providers top-notch quality and care.

Our technicians have more than 60 years of combined experience in a wide array of services. Our repair technicians are factory-trained, and are skilled at working with highly technical pieces. We offer local and remote support, and have a loaner program should your piece need more extensive service or repair.

Technicians are also trained and able to help you set up your layout and lane moves. We can help determine the best placement for equipment and electrical needs to maximize your efficiency. We can assist with practice layouts, and when it comes time for the move, we can recalibrate your full lane.

An ounce of prevention is worth a pound of cure, and our general maintenance program goes above and beyond an ounce. We offer cleaning, phoropter maintenance, and service for each piece of your lane, as well as full warranty support.

Call us to today to learn more about keeping your equipment in the best shape and your office running smoothly.